How To Test A Washing Machine Motor

Tracy Beard / Friday October 20, 2023

Tracy Beard

The motor in your washing machine is a critical component that allows the drum to spin and agitate your clothes to get them clean. Over time, the motor can start to fail, leading to problems with spinning, strange noises, and mid-cycle stopping. Knowing the signs of a failing washer motor and how to test for and diagnose problems can help you determine if motor replacement is needed.

The washer motor powers the drum and drive train to agitate and spin during wash cycles. Issues like the washing machine won’t spin, strange humming or buzzing noises, or failure to complete cycles can all indicate potential motor failure. Catching motor problems early allows for easier repairs. Ignoring the symptoms can lead to total motor burnout and more complex fixes.

Symptoms of a Failing Washer Motor

Several common symptoms can signify that the motor on your washer is wearing out or defective:

Washer Won’t Spin or Agitate Clothes

One of the most obvious signs of motor trouble is when the washer fails to perform its wash and spin cycles. This includes:

- The washer drum not spinning at all

- Drum spinning weakly or slowly

- Clothes not being agitated/moved during the wash cycle

- Washer starts to fill and drain but the drum doesn’t move

If you find the washer is not spinning or washing properly, the motor could be burned out. Motor windings can overheat and lose conductivity, resulting in failure to start or turn.

Loud Noises from Washer During Cycles

As electric motors wear out, you may notice strange noises coming from the washer during operation:

- Humming or buzzing sounds

- Squeaking or screeching noises

- Loud banging or clanking

- Grinding when the motor tries to start

These types of noises can indicate bearings are worn or the rotor rubbing in the stator. Electrical issues can also cause odd sounds. Always unplug the washer before inspecting the motor if you hear unusual noises.

Washer Stops Mid-Cycle

When a washer stops mid-cycle it is often caused by an overheated motor. The motor may run for a while but as it overheats it will shut off to prevent permanent damage. This is a protective feature but signals the motor needs maintenance or replacement.

Spin Cycles Less Effective

Over time you may notice the motor seems weaker and unable to spin clothes effectively. It may take multiple cycles to get loads fully dry. This reduced performance points to a worn motor losing winding strength. Weaker spin can also result in mildew smells in the washer.

Washer Motor Clicking, Buzzing or Humming

Specific noises when the motor first starts up or tries to spin can provide clues to issues:

- Rapid clicking may indicate bad bearings

- A buzzing noise can signal damaged windings, motor capacitor, or start capacitor.

- A humming motor that won’t start likely has stuck brushes

Any mechanical or electrical noise out of the ordinary warrants inspection of the motor.

Read more: Tips For Preventing Laundry Damage in Your Washing Machine

Testing the Washing Machine Motor

Pinpointing problems with the washer motor involves electrical and mechanical testing. Always make sure to unplug the washer before conducting DIY motor diagnosis.

Check Wiring and Connections

Loose or disconnected wires between the motor and control board can cause spin and agitate failures. Check that all wiring is securely attached to the motor terminals. Look for any corroded or burnt wires as well. Tighten any loose electrical connections.

Test Winding Resistance

Use a multimeter set to OHMs to test the winding resistance in the motor. The readings indicate the condition of the copper windings. First, find the wiring diagram for your specific washer model to determine the correct ohm range for each winding. Compare your readings:

- If winding resistance is zero, there is likely a broken or shorted winding.

- Very high resistance points to an open winding.

- Readings outside the specification range can signify degraded windings.

Significant deviation in windings resistance indicates motor electrical failure. Writing down the measurements can help for diagnosis.

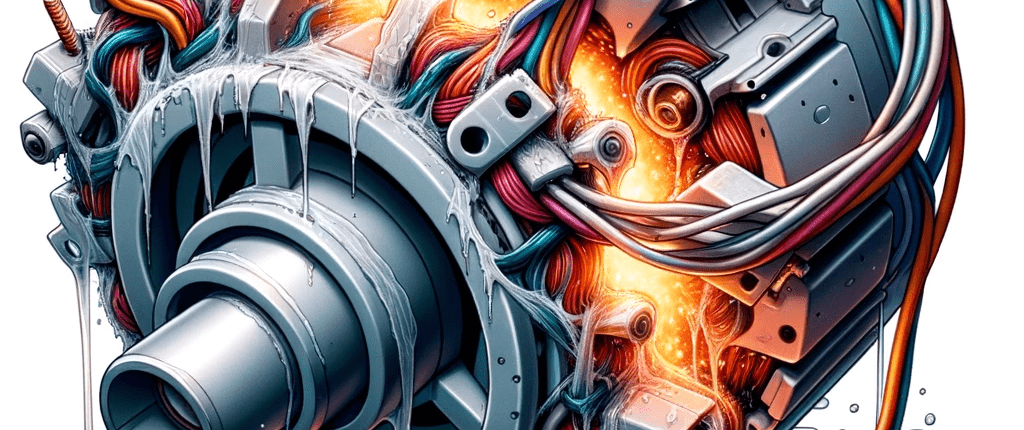

Inspect Motor Windings and Brushes

With the motor disassembled or opened up, check the windings for signs of overheating. Look for:

- Discoloration or burnt coils

- Melted wires or insulation

- Charring on the windings

- Deformed or warped coils

Darkened, burnt or warped windings often means the motor needs replacement due to permanent damage.

Also check the motor brushes and commutator segments for excessive wear. The brushes should slide freely in their holders. Dark, worn brushes need to be replaced.

Manual Motor Spin Test

To check the motor pulley and bearings, try slowly rotating the pulley by hand. Problems can be felt or heard:

- Grinding, and scraping noises can indicate bad bearings

- A jerky or stiff movement as you turn means the bearings worn

- Loose pulley on shaft signals end bearing wear

Noise or too much resistance rotating means the motor bearings may be worn out. The bearings would need to be replaced.

Listen for Unusual Noises

With power disconnected, try turning the motor pulley while listening closely for odd sounds. This can help diagnose washing machine motor part issues like bad rotor, worn carbon brushes or damaged bearings. Squealing, growling or knocking noises signal problems inside the motor.

Using the above electrical and mechanical tests will help narrow down whether the washer motor needs to be repaired or replaced.

Read more: How to Fix a Washing Machine That Smells Bad

When to Replace a Bad Washer Motor

Replacing the motor is required once it can no longer reliably agitate and spin at the proper speeds. Here are scenarios that typically require full motor replacement:

Severe Overheating Damage – If internal windings are burnt or coils warped, the motor components are permanently damaged. This requires a full motor swap.

Failed Electrical Testing – Significantly high or low ohm readings during resistance tests usually means new motor time. Shorts and opens signal winding damage.

Locked Rotor – If the pulley cannot be rotated at all by hand, the interior rotor is jammed and necessitates replacement.

Bad Bearings – Excess bearing noise, stiffness and resistance turning the shaft call for a new motor with fresh bearings.

Old Age – Most washer motors last 5-10 years. If your motor is older and noisy or performs poorly, replacement is the best fix.

When troubleshooting confirms the motor is mechanically or electrically shot, replacement is the permanent solution. Repairing a marginal motor may lead to more future failure.

How to Replace a Washing Machine Motor

Follow these steps to safely replace a bad washer motor:

Unplug Washer and Turn Off Water

Before any work, unplug the washer from the electrical outlet. Make sure power cannot be turned back on accidentally. Also, turn off the hot and cold water lines to prevent flooding during motor swap.

Access the Motor Compartment

For most washers, the motor is housed in the bottom rear of the cabinet. Removing the back service panel or front bottom panel allows motor access. Refer to your appliance manual for detailed location info.

Disconnect Old Motor Wiring

The motor wires, capacitor wires (if present) and ground screw must be detached. Label wires to ensure correct reconnection later. Use needle-nose pliers if wires are stuck on terminals.

Remove Mounting Bolts

There are usually 2-4 bolts fastening the motor mount arms or straps to the frame. Loosen these using a socket wrench so the motor is released. Support the weight of the motor before the last bolt.

Lift Out Old Motor

With wiring off and bolts out, carefully lift the old motor out of the machine. Note the position of any shims or rubber isolators between the motor and mount for reinstallation. Set the old motor aside.

Install New Motor

Set replacement motor into mounting position. Reinstall any shims or isolators in their original locations. Insert mounting bolts and tighten them securely. Do not overtighten bolts.

Reconnect Wiring

Using your wiring labels, attach each wire terminal back to the matching motor connection. Double check connections are tight. Secure grounding screw. Tuck wires neatly away before replacing service panels.

Test Operation

With the new motor installed and plugged in, run a test spin cycle. Listen and look for normal operation before washing clothes again. The fresh motor should run smoothly and quietly.

Take safety precautions when replacing a washer motor. Wear gloves, disconnect power, and support heavy parts to avoid injury. If needed, consult a professional appliance repair company to change out the motor.

Preventing Washer Motor Failure

Certain maintenance habits and washing best practices can maximize the lifespan of your washer motor:

- Clean Lint Filters Regularly – Built-up lint can clog vents, reducing air circulation. This can cause overheating around the motor. Clean screens after each load.

- Avoid Overloading – Jamming too many clothes into the drum puts strain on the motor. Run smaller loads that allow clothes to move freely to prolong motor life.

- Let Washer Rest Between Loads – Don’t start new cycles immediately after finishing. Give the motor several minutes to cool fully between runs.

- Use Gentler Wash Cycles – Harsher cycles with high spin speeds tax the motor. When possible, choose lighter settings like delicate or permanent press.

- Check Drive Belt – A loose or broken drive belt that slips can cause extra motor wear. Inspect the belt yearly and replace it if damaged.

- Level the Washer – An off-balance washer vibrates more, wearing the motor bearings. Confirm all leveling feet are adjusted properly.

- Clean and Lubricate – Over time, dirt and soap residue can stick to motor parts. Wipe down the exterior and apply new grease yearly.

Read more: Washing Machine Won’t Spin: Top 7 Problems and Fixes for Top-Loading and Side-Loading Washers

Reach Out to Us

Monitoring your washer motor and avoiding overuse will provide the longest possible motor service life before replacement becomes necessary.

Issues like the washing machine not spinning, loud buzzing or humming, failure to agitate, or stopping mid-cycle can signify washer motor problems. Conducting resistance testing and mechanical checks of the motor windings, bearings and wiring can help diagnose issues.

Thanks for reading! If you have any other appliance repair needs or projects, you can find other resources and our DIY blog at AppliancePartsPros.com. There, you can enter your model number to order the exact parts you need. Most orders arrive in 2-3 business days.

You can also reach our award-winning customer service team at 1-877-477-7278, chat with a pro on our website and watch thousands of free video tutorials on our YouTube channel.

Make sure to follow us on Facebook, Twitter and Instagram!

Hello there! I’m Tracy, and I’m thrilled to be part of the Appliance Parts Pros team. With two years of service and hands-on experience here, I’ve had the privilege of helping numerous customers troubleshoot their home appliances and find DIY repair solutions.