What is Dishwasher Insulation and Why is it Necessary?

Steven E / Monday August 21, 2023

When it comes to the appliances in our homes, we often overlook the hidden components that play a crucial role in their efficient functioning. Insulation may not be the first thing that comes to mind when thinking about dishwasher maintenance, but it plays a significant role in the appliance’s performance. Whether you’re a DIY enthusiast or just curious about inner workings, understanding the importance of dishwasher insulation will help you appreciate the appliance’s efficiency and take proper care of it. Here’s why dishwasher insulation is necessary and how it contributes to overall functionality.

Importance of dishwasher insulation

Dishwasher insulation acts as a thermal barrier and prevents heat loss during the wash cycle. It also helps contain the heat generated by the dishwasher’s heating elements, ensuring that the water inside reaches and maintains the desired temperature. Without proper insulation, heat would dissipate, resulting in longer cycle times and less effective cleaning.

Keeping the water inside the dishwasher at a consistent temperature throughout each wash cycle is crucial for effective cleaning, since certain detergents and enzymes work optimally within specific temperature ranges. Insulation helps the dishwasher maintain the required temperature, to ensure a thorough and efficient cleaning of dishes.

By minimizing heat loss, dishwasher insulation contributes to energy efficiency. When the dishwasher’s temperature is maintained more effectively, it reduces the need for additional energy to heat the water. This translates into lower energy consumption, leading to cost savings on your utility bills and more environmentally friendly operations.

Dishwasher insulation composition

Dishwashers use various types of insulation materials to help maintain the best temperatures and protect their components:

Foam insulation: Common types used in a dishwasher include polyurethane and polyethylene foams. They are typically used around the tub, inlet pipe, and door seal area to contain heat.

Fiberglass insulation: Glass wool and fiber batting insulation is usually installed behind internal metal panels to block heat transfer through the outer walls/cabinet.

Ceramic fiber insulation: High-temperature ceramic fibers are often wrapped around heating elements, inlet pipes, and steam tubes to withstand hot water/steam temperatures.

Mineral wool insulation: Composed of mineral fibers, this is another high-heat option used around critical heating components.

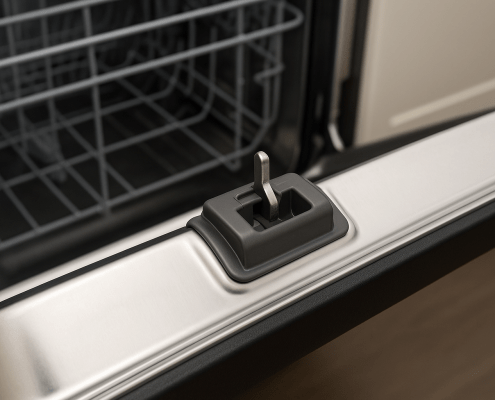

Gaskets and seals: Rubber seals, weatherstripping, and door gaskets further insulate the dishwasher tub from the outer cabinet and help reduce noise/vibration during operation.

Thermal break barriers: Plastic barriers help separate metallic door components from the tub to prevent “bleeding” of temperatures between interior and exterior surfaces.

Purpose of dishwasher insulation

Noise reduction

Kitchens are often bustling spaces, and excessive noise from appliances can be disruptive.

Proper insulation significantly improves sound vibration absorption by reducing the sound generated by the dishwasher. Foam insulation can help absorb and dampen the noise produced by the internal components such as the motor, pumps and spray arms, creating a more peaceful and enjoyable kitchen environment.

Moisture control

Insulation also plays a vital role in preventing condensation from forming on the outer surfaces of the dishwasher. During the wash and dry cycles, the interior generates steam and moisture. The insulation helps contain this moisture and prevents it from reaching the exterior of the appliance, which protects the dishwasher’s exterior from water damage and ensures its longevity.

By controlling moisture, proper insulation safeguards adjacent cabinets and countertops from potential water damage. Without insulation, condensation can accumulate and seep into nearby wooden or laminated surfaces, leading to swelling, warping or discoloration. Insulation acts as a barrier and prevents these issues, preserving the aesthetics and structural integrity of your kitchen.

Signs of insulation problems

Insulation in a dishwasher is designed to last, but there may be instances where it can deteriorate over time. It’s important to recognize the signs of potential problems so the insulation can be repaired if necessary.

Here are some common indicators to watch out for:

Excessive heat loss

If you notice that your dishwasher is taking longer than usual to heat up the water or maintain the desired temperature, it could be a sign of insulation heat loss. Poor insulation may allow heat to escape more easily, leading to inefficient heating and longer cycle times. Be sure to monitor the dishwasher’s performance and note any significant changes in heating efficiency to help identify insulation issues.

Increased noise levels

If you observe a sudden increase in noise levels while operating the dishwasher, it could indicate insulation deterioration or damage. Faulty insulation may fail to absorb and dampen the sounds generated by the dishwasher’s internal components, resulting in louder performance. Pay attention to any unusual or persistent noise that seems out of the ordinary.

Water leaks or moisture accumulation

If you notice water leaks around the dishwasher or moisture accumulation on adjacent surfaces such as cabinets or countertops, it could signify damaged or deteriorated insulation. This may allow moisture to escape from the dishwasher, leading to potential water damage or the growth of mold and mildew.

Physical damage to insulation

Insulation can suffer physical damage over time due to various factors such as age, wear and tear or accidental impact. Check the insulation material around the dishwasher for any visible signs of steam damage, such as cracks, tears or gaps. Steam damage compromises the insulation’s effectiveness and should be addressed promptly.

Energy inefficiency

If you notice a significant increase in your energy bills without any apparent change in dishwasher usage or settings, it could be an indication of insulation heat loss. Inadequate insulation may lead to more energy being required to heat the water, resulting in higher energy consumption.

WATCH: How to replace Frigidaire/Electrolux dishwasher insulation

Insulation repair and replacement

Over time, dishwasher insulation may deteriorate or become damaged. Whether you’re experiencing signs of insulation problems or simply looking to maintain your dishwasher’s efficiency, understanding the process of insulation repair or replacement will empower you to take the necessary steps to ensure your appliance functions at its best. Let’s see how to address insulation issues and guarantee the smooth operation of your dishwasher:

- Safety first: Before starting any repair work, ensure that the dishwasher is disconnected from the power supply. Unplug the appliance or turn off the circuit breaker dedicated to the dishwasher to avoid any electrical accidents.

- Assess the insulation: Carefully examine the insulation material around the dishwasher. Look for signs of damage, such as cracks, tears or gaps. If you notice any significant wear or damage to the insulation blanket or foam, it may need to be replaced.

- Obtain the right replacement materials: Locate the Original Equipment Manufacturer (OEM) parts for your model to get the correct type and dimensions for insulation material. Replacing appliance parts with OEM parts is crucial to ensuring the optimal functioning, safety and longevity of your appliances. OEM parts are designed and manufactured to the exact specifications of the original appliance, guaranteeing a proper fit and compatibility. You can find OEM parts for your model number here.

- Remove the old insulation: If the insulation is damaged or worn out, gently remove it from the dishwasher. Take care not to damage any other components during this process.

- Install the new insulation: Cut the replacement insulation material to fit the dimensions of the dishwasher’s interior. Carefully attach or secure the new insulation by following the manufacturer’s guidelines or use adhesive as recommended. Make sure the piece covers all necessary areas to provide effective thermal insulation and noise reduction.

- Test the dishwasher: Once the new insulation is installed, reconnect the power supply and test the dishwasher to ensure it functions properly. Monitor for any changes in performance or noise levels.

Note: The above steps are general guidelines, and specific instructions may vary depending on the dishwasher model and the type of insulation used.

More information

Understanding the specific reasons for insulation around a dishwasher allows us to appreciate its importance. By recognizing the signs of insulation problems, such as excessive heat loss, increased noise and water leaks, we can address these issues in a timely manner.

Remember that a well-insulated dishwasher ensures clean and sparkling dishes and contributes to a more enjoyable and functional kitchen space. Be sure to take the necessary steps to maintain and repair the insulation in your dishwasher, and you’ll reap the benefits of a well-performing and long-lasting appliance!

If you need replacement parts for your appliance, grab your model number and head over to AppliancePartsPros.com, where you can use our compatibility tool located below all of our listed parts. Once there, you can also chat with a pro, speak with customer service, and find more guides on our DIY blog.

Be sure to subscribe to our YouTube channel for thousands of free video tutorials and follow us on Facebook and Twitter for updates.

With nearly a decade of experience in providing top-notch customer service regarding appliance parts and repair, Steven enjoys sharing practical advice, troubleshooting tips, and interesting information to help readers stay informed.