How to replace the control board jumper wire on a GE dishwasher

Steven E / Thursday May 15, 2025

Is your GE dishwasher not turning on or powering up? The issue could be a faulty jumper wire (WD21X23559) connecting to the control board. Replacing this small part can get your appliance cleaning dishes again. It’s an easy do-it-yourself fix you can complete in a few minutes. With some basic tools and a new jumper wire, you can handle this repair yourself and save the cost and hassle of a service call.

The information in this article may not apply to your specific appliance model. We recommend consulting your manufacturer’s documentation or contact us with any questions.

What is the jumper wire?

The jumper wire in a GE dishwasher provides power from the junction box to the control board. It’s a small gauge wire with connectors on each end. Over time, this wire can become damaged or corroded, interrupting power to the control panel. If your dishwasher suddenly stops operating, won’t start cycles, or lacks any interior lights, the jumper wire is the first thing to check. Replacing it is a straightforward repair anyone can tackle.

In this guide, we’ll walk through the full process of changing out a faulty dishwasher jumper wire. You’ll just need some common tools and a compatible replacement part.

Tools and parts needed

Gather the following tools before accessing the dishwasher junction box and control board:

- 5/8 inch wrench – For removing water lines

- 5/16 inch nut driver – For detaching drain hose

- Phillips screwdriver – For dishwasher mounting screws

- 1/4 inch nut driver – For access panel screws

- Replacement jumper wire – GE part number WD21X23559

Safety precautions

Safety should always be a priority when working on any appliance. Here are a few practical tips to help you stay safe:

- Turn off the power to the appliance by unplugging it or switching off the circuit breaker before starting any maintenance or repairs. This protects you from the risk of electric shock.

- Wear insulated gloves to shield your hands from sharp edges, pinching hazards, or debris.

- Work at a steady pace and take your time to avoid accidents or injuries.

- Make sure your workspace is well-lit so you can clearly see and access the parts you’re working on.

- Keep the area clear of clutter, and ensure children and pets stay out of the workspace.

- Never handle internal parts with wet hands. Check that both your hands and the work area are completely dry.

- Refer to your appliance’s user manual for any specific instructions or safety guidelines related to the part or repair.

- Handle parts gently to avoid damage to the appliance or potential injuries from applying too much force.

- Use safety glasses when dealing with chemicals, dust, or large debris to protect your eyes from harm.

- If the appliance was recently used, give it enough time to cool down before working on any heated components.

- Take photos or notes of wiring connections and terminals before disconnecting anything to make reassembly easier.

- Avoid touching exposed wires or terminals. If you must handle wires, use non-conductive tools or wear insulated gloves to minimize the risk of electrical shock.

Disconnecting the dishwasher

With the electrical and water supplies disconnected, we’re ready to pull out the dishwasher:

- Locate the water fill line and drain hose connected to the underside of the dishwasher. Loosen the hoses and clamps using a wrench and nut driver. Have a towel ready to catch any water still in the lines.

- Open the dishwasher door and pull out both upper and lower racks. Use a Phillips screwdriver to remove the screws securing the unit within the cabinet. Carefully pull the dishwasher forward.

Accessing the control board

Once the dishwasher is fully extracted, we can begin disassembling it to access the jumper wire:

- Carefully lay the dishwasher on its back on top of a towel or blanket. Remove the screws from the lower access panel using a 1/4-inch nut driver. Detach the panel and insulation inside.

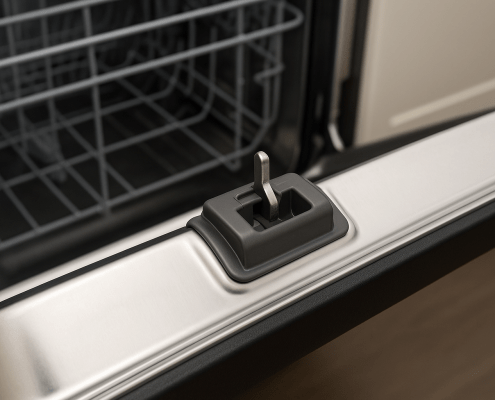

- Locate and remove the small cover over the jumper wire junction box. Save the cover screw for later reinstallation.

- Use the nut driver to detach the two ground wires from their mounting point. These will allow the junction box to hang freely.

Replacing the jumper wire

With the junction box now accessible, we can replace the defective jumper wire:

- Make note of the wire nut connections, then unscrew them to detach the ends of the old jumper wire. Also, unplug the wire from the control board.

- Insert the new OEM replacement jumper wire into the control board socket until it clicks into place. Twist on the wire nuts, matching the previous wire configuration.

- Screw the ground wires back into place on the junction box bracket using the 1/4-inch nut driver.

- Position the small junction box cover back over the wiring, inserting the locking tab into the proper slot. Screw the cover securely in place.

Reassembling the dishwasher

With the new part installed, we can reassemble the appliance:

- Replace the insulation and access panel, tightening all screws with the nut driver.

- Carefully lift the dishwasher back into an upright position, removing the towel underneath.

- Feed the drain hose and water line back through the cabinet opening. Push the dishwasher partially in, then attach the lines underneath.

- Once attached, push the dishwasher fully back into position within the cabinet.

- Use the Phillips screwdriver to reinsert the screws along the underside of the tub, securing the unit tightly.

- Finally, slide the dishwasher racks back into place on their rails.

More information

If you need any replacement parts for your appliances, you can enter your model number at AppliancePartsPros.com to locate and order them quickly. Most orders arrive in just two business days, and we have tons of great information in our repair help section and YouTube videos to help you troubleshoot.

Stay connected with the latest DIY tips, tutorial videos, and repair guides by following us on Facebook, Instagram, and Twitter. We love hearing about your repair stories and successes. If you need more help or want personalized guidance, feel free to reach out. We’re ready to help you take on your next project with confidence!

With nearly a decade of experience in providing top-notch customer service regarding appliance parts and repair, Steven enjoys sharing practical advice, troubleshooting tips, and interesting information to help readers stay informed.